|

"Crisper"

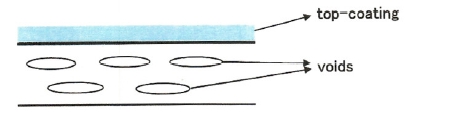

is the White Opaque Synthetic Paper based on Polyester

which contains numerous voids in it and is top-coated

to promote adhesion to most printing inks and industrial coatings.

These features allow us to offer the following advantages for RFID

application and "Crisper" is an optimal material for RFID compared

to other materials including paper, regular PET film, PP and olefin

related film etc.

Numerous

voids

-

Cushioning

Property

Due to the numerous voids, the specific gravity of "Crisper" is

1.1g/cm3 while that of regular PET film is normally 1.4g/cm3,

which enables "Crisper" to provide its cushioning property.

IC chips and lead wires are embedded in or sandwiched between

materials in most RFID labels and tags. In whatever form, during

these converting processes, there is an unavoidable amount of

pressure applied to the material. This pressure often causes damage

to the chips and lead wires, which raises the loss ratio as well

as material loss. "Crisper" can reduce this loss ratio due to

its cushioning property compared with the use of regular white

PET.

- Low Dielectric

Loss

The dielectric constant of "Crisper" lies between Polypropylene

and PET film. The dielectric loss of "Crisper" is smaller than PET

film. That's why the absorption of the electromagnetic wave is little

and the energy effectiveness is good. "Crisper" is recommended to

use Flat cable, Communication cable, IC Card and IC Tag.

- Recognition

Rate

Because the dielectric loss of "Crisper" is small, there will be

much fewer errors in reading the chip.

- Electric

Property

The volume resistance of Crisper is  and

is used as insulating material.

and

is used as insulating material.

- Thermal

Property

The insulating characteristics of "Crisper" is suited to Re-Writable

coating for direct thermal. The numerous voids trap heat which allows

printed characters to appear and disappear sooner with less energy

used than with the other related material.

Based on

PET

- "Crisper" offer

higher heat resistance than paper and polypropylene film. For some

RFID labels and tags, electrically conductive lead(lead wire) is

imprinted using copper ink. After printing, some heat has to be

applied to the material for curing purposes by a hot-air dryer.

"Crisper" can endure this heat because of being PET base, while

paper and polypropylene material cannot.

- Durability

"Crisper" has better durability than paper and polypropylene film.

The customers can anticipate that the total cost will be reduced

with repeated use.

- Stability

"Crisper" is more stable (Adherence, Thermal Resistance, Shrinkage)

than paper and polypropylene film, which makes any converting process

easier and faster.

- Chemical

Resistance

"Crisper" has a Chemical Resistance against acid, alkali solvent,

organic solvent and so on.

Top Coating

- Printability/Adhesion

Property

The uniquetop-coating of "Crisper" has an excellentaffinityto various

printing inks, resins and industrial coatings. Re-write coating

for direct thermal can be made on the surface of "Crisper".

- Anti - Static

property

The top coating contains an anti-static agent, which leads to the

reduction of damage to IC chips by static discharge.

Note:

We believe this information is the best currently available on the

subject. It is subject to revision as additional knowledge and experience

is gained. We strongly recommendthat a trial run be carried out and

the careful evaluation be done for a specific application before commercial

use. We make no warranty and assume no liability whatever in connection

with any use of this information.

|